Bedankt voor het vertrouwen het afgelopen jaar! Om jou te bedanken bieden we GRATIS verzending (in België) aan op alles gedurende de hele maand januari.

- Afhalen na 1 uur in een winkel met voorraad

- In januari gratis thuislevering in België

- Ruim aanbod met 7 miljoen producten

Bedankt voor het vertrouwen het afgelopen jaar! Om jou te bedanken bieden we GRATIS verzending (in België) aan op alles gedurende de hele maand januari.

- Afhalen na 1 uur in een winkel met voorraad

- In januari gratis thuislevering in België

- Ruim aanbod met 7 miljoen producten

Zoeken

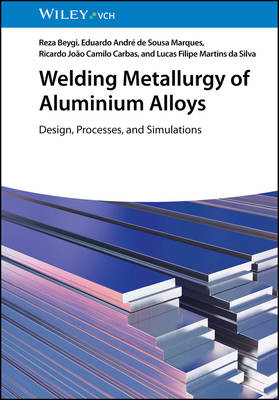

Welding Metallurgy of Aluminium Alloys

Design, Processes, and Simulations

Reza Beygi, Eduardo André de Sousa Marques, Ricardo João Camilo Carbas, Lucas Filipe Martins Da Silva

Hardcover | Engels

€ 137,45

+ 274 punten

Omschrijving

Provides the tools to and discusses the welding of aluminium alloys, defect analysis and the necessary heat conductivity equations

Specificaties

Betrokkenen

- Auteur(s):

- Uitgeverij:

Inhoud

- Aantal bladzijden:

- 208

- Taal:

- Engels

Eigenschappen

- Productcode (EAN):

- 9783527353347

- Verschijningsdatum:

- 10/11/2025

- Uitvoering:

- Hardcover

- Formaat:

- Genaaid

- Afmetingen:

- 170 mm x 244 mm

- Gewicht:

- 666 g

Alleen bij Standaard Boekhandel

+ 274 punten op je klantenkaart van Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.