- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

Zoeken

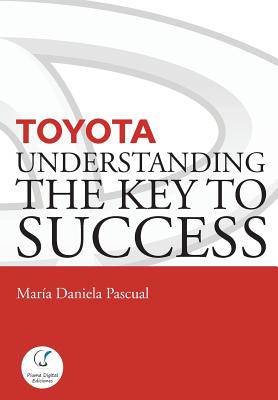

Toyota

Understanding the Key to Success: Principles and strengths of a business model

María Daniela Pascual

€ 26,45

+ 52 punten

Omschrijving

Toyota is recognized as a successful car manufacturer based on its production and cost reduction systems. When analyzed in depth, the company's evolution is astonishing. The effect of the Lean Philosophy and its fundamental principles on Toyota's organizational systemic model is analyzed from an economic perspective. This study covers both the positive effects generated by the Toyota model at its three organizational structure levels and the collateral negative effects generated by the company's corporate strategy. - The conjunction of these effects gives rise to an integral transaction cost reduction with positive economic effects, a fact not sufficiently recognised by those who believe Toyota's success is simply the result of inventory control using the successful JIT system. Research and analysis of the Toyota case have been plentiful in many fields as diverse as production, marketing, business planning, and knowledge management., thecompany's work methods, its results, and the adverse conditions from which it has emerged so many times over its 75-year history have drawn the attention of researchers and businessmen. At Toyota something is wrong when workers do not look around every day, notice tedious or boring things, and then redesign the processes. Even the latest monthly manual could be out-of-date. Toyota's incredible success is a source for inspiration for many business leaders around the world. Be you one of them!

Specificaties

Betrokkenen

- Auteur(s):

- Uitgeverij:

Inhoud

- Aantal bladzijden:

- 246

- Taal:

- Engels

- Reeks:

Eigenschappen

- Productcode (EAN):

- 9789872909956

- Verschijningsdatum:

- 14/09/2015

- Uitvoering:

- Paperback

- Formaat:

- Trade paperback (VS)

- Afmetingen:

- 170 mm x 244 mm

- Gewicht:

- 399 g

Alleen bij Standaard Boekhandel

+ 52 punten op je klantenkaart van Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.