- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

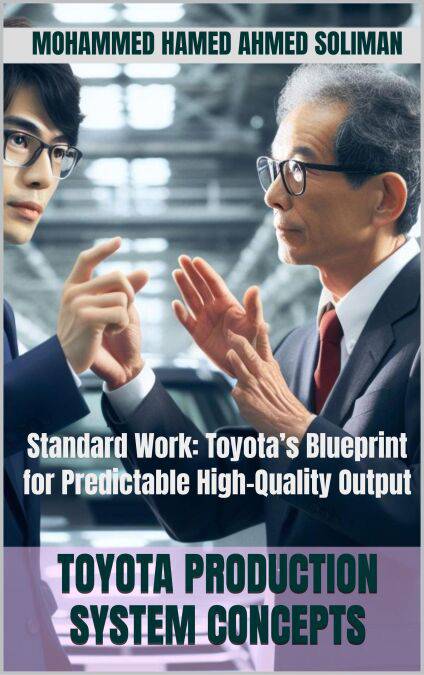

Lean Pull & Kanban: How to Make Flow Visible and Eliminate Overproduction E-BOOK

Toyota Production System Concepts

Mohammed Hamed Ahmed SolimanOmschrijving

Pull production starts where most systems end — with the customer.

Unlike traditional production where products are pushed into the market hoping someone will buy, pull production begins by listening to what is actually needed — how much, when, and where.

In this clear and practical guide, Dr. Mohamed H. Soliman explains how pull systems work, how they reduce overproduction, and how they connect to Just-in-Time (JIT) as part of Toyota's lean philosophy.

You'll learn:

How downstream steps signal upstream steps for what is needed Why pull is the opposite of "make-to-stock" thinking The role of Kanban as the visual tool that enables pull How Pull, Takt, and Flow form the three pillars of JIT Why Heijunka (Leveling) is the foundation behind them all Real examples of pull in factories and service organizationsWhether you are just starting with Lean or improving an existing system, this book gives you the mindset, methods, and steps to make Pull Production work in the real world.

Because flow starts with demand — not guesswork.

Specificaties

Betrokkenen

- Auteur(s):

- Uitgeverij:

Inhoud

- Taal:

- Engels

- Reeks:

Eigenschappen

- Productcode (EAN):

- 9798215942802

- Verschijningsdatum:

- 25/10/2023

- Uitvoering:

- E-book

- Beveiligd met:

- Adobe DRM

- Formaat:

- ePub

Alleen bij Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.