- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

Zoeken

€ 67,45

+ 134 punten

Omschrijving

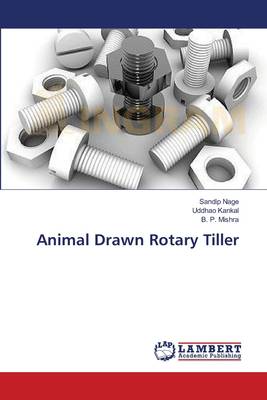

Rotary tiller also known as rotavator, has gained popularity in last two decades. It is versatile implement, which can be used in variety of soils and leaves the soil in well pulverized condition. In fact, it does the job of three implements namely, tiller, harrow and leveller; thus it will not be wrong to say that rotavator is three implements rolled into one. There is evidence that such a tilth gives a good start to the seed and results in an increased rate of growth in its early stages. It is suitable for preparing well seed-bed. Looking to the versatility and utility of rotary tiller, and the large command area under animal farming system, an animal operated rotary tiller needs to be introduced. As rotary type implements have good scope for seedbed preparation and intercultural operations in most of the timely crops. Animal drawn rotary tiller has not yet introduced, probably due to difficulty in providing rotary motion. Most of the developed puddler and harrows are trailed type only therefore proper seedbed preparation is not obtained. In developed rotary tiller the power requirement and quality of tilth depend on the shape of tines,spacing,number of tines and cutting angle

Specificaties

Betrokkenen

- Auteur(s):

- Uitgeverij:

Inhoud

- Aantal bladzijden:

- 104

- Taal:

- Engels

Eigenschappen

- Productcode (EAN):

- 9783659551345

- Verschijningsdatum:

- 29/05/2014

- Uitvoering:

- Paperback

- Afmetingen:

- 150 mm x 220 mm

- Gewicht:

- 163 g

Alleen bij Standaard Boekhandel

+ 134 punten op je klantenkaart van Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.