- Afhalen na 1 uur in een winkel met voorraad

- In januari gratis thuislevering in België

- Ruim aanbod met 7 miljoen producten

- Afhalen na 1 uur in een winkel met voorraad

- In januari gratis thuislevering in België

- Ruim aanbod met 7 miljoen producten

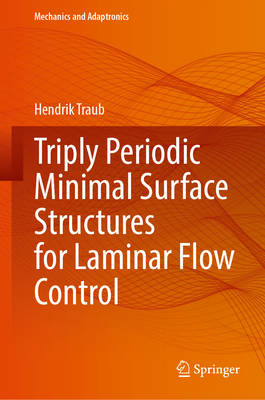

Triply Periodic Minimal Surface Structures for Laminar Flow Control

Hendrik TraubOmschrijving

Laminar flow control systems promise substantial emission reductions by minimising the viscous drag of transport aircraft. While boundary-layer suction has been proven in wind tunnel and flight tests, no system effectively improving the energy efficiency of transport aircraft is available. This doctoral thesis develops an additively manufacturable suction panel for laminar flow control, reducing the technology's complexity into one integral component decoupled from the aircraft's main structure. The benefit of additive manufacturing is the integration of complex aerodynamic requirements, such as surface curvature and suction rate control, into the suction panel's design.

Manufacturing micro-perforations of the same size as the resolution of industrial 3D printers is challenging. This thesis investigates printable perforation geometries for various additive manufacturing technologies. Identifying their porosity and pressure drop characteristics enables the selection of suitable geometries and technologies to produce micro-perforated surfaces for boundary-layer suction. Stereolithography-printed surfaces with quadratic-truncated-cone perforations effectively delay the laminar-turbulent transition in flat-plate wind tunnel tests.

Under aerodynamic loading, the micro-perforated surface requires a dense support structure, simultaneously enabling air discharge. However, due to insufficient internal airflow, support structures such as Honeycombs or foams cannot be used. In contrast, triply periodic minimal surfaces offer significant internal airflow while providing dense mechanical support. This thesis investigates the design and mechanical performance of triply periodic minimal surface structures and presents a prediction model based on their relative density. A wing-sizing study employs this model to demonstrate the suction panel's minimal impact on the wing mass.

Ultimately, this doctoral thesis presents a design for an additively manufactured suction panel that meets the mechanical and aerodynamic requirements of laminar flow control and aircraft wing design. Successful suction panel component tests result in a design methodology that enables effective transition delay and integrated passive suction rate control. The additively manufactured suction panel reduces complexity and expands the applications of laminar flow control technology. Consequently, the suction panel concept developed in this thesis promises to be a key technology for next-generation transport aircraft with increased energy efficiency.

Specificaties

Betrokkenen

- Auteur(s):

- Uitgeverij:

Inhoud

- Aantal bladzijden:

- 164

- Taal:

- Engels

- Reeks:

Eigenschappen

- Productcode (EAN):

- 9783032138439

- Verschijningsdatum:

- 6/02/2026

- Uitvoering:

- Hardcover

- Formaat:

- Genaaid

- Afmetingen:

- 155 mm x 235 mm

Alleen bij Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.