- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

Zoeken

Omschrijving

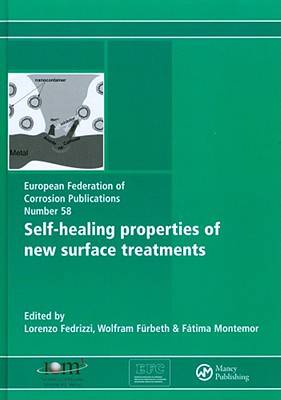

All branches of industry have, for many decades, utilised organic coatings with active pigments. In most cases the pigments have included zinc dust, red lead oxide or chromates, the protective mechanisms of which are well understood. However, the use of lead and chromate-based coatings is no longer permitted, due mainly to their toxic and carcinogenic characteristics, respectively. This has stimulated much interest in the development of new environmentally-friendly coatings with active pigments that convey self-healing characteristics. The use of advanced primers containing smart self-healing pigments with up to four cooperative effects aims to provide enhanced corrosion resistance for steel or aluminium structures. This publication was motivated by the highly successful workshop on self-healing coatings held on 12 September 2007 at the European Federation of Corrosion's annual EUROCORR conference in Freiburg. It includes sixteen contributions, some of which were selected from the proceedings of the workshop (often in extended form) together with a number of specially invited articles and reviews. Among the coatings discussed are: organosilane films filled with nanoparticles and corrosion inhibitors; nanoparticle-containing polyaniline films; pyrrole-based silane primers; polypyrrole/aluminium flake hybrid pigments; ZrO2 sol-gel films; cerium-containing silica methacrylate sol-gel coatings, and many others

Specificaties

Betrokkenen

- Auteur(s):

- Uitgeverij:

Inhoud

- Aantal bladzijden:

- 307

- Taal:

- Engels

- Reeks:

- Reeksnummer:

- nr. 58

Eigenschappen

- Productcode (EAN):

- 9781906540364

- Verschijningsdatum:

- 31/05/2011

- Uitvoering:

- Hardcover

- Formaat:

- Genaaid

- Afmetingen:

- 180 mm x 249 mm

- Gewicht:

- 793 g

Alleen bij Standaard Boekhandel

+ 475 punten op je klantenkaart van Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.