- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

Zoeken

Omschrijving

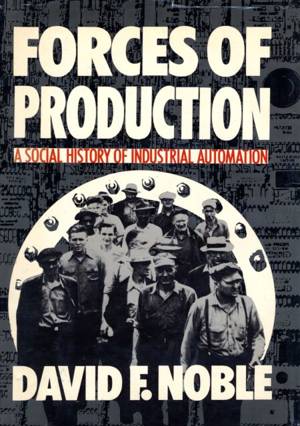

Focusing on the design and implementation of an important new production technology—computer-based automatic machine tools—David F. Noble challenges the idea that technology has a life of its own which proceeds along a singular path. Such as seen, technology has been both a convenient scapegoat and a universal panacea, serving to disarm critics, divert attention, depoliticize debate, and dismiss discussion of the fundamental antagonisms and inequalities that continue to beset America. This provocative study of the postwar automation of the American metal-working industry—the heart of a modern industrial economy—explains how dominant institutions like the great corporations, the universities, and the military, along with the ideology of modern engineering, actually shape the development of technology itself.

Noble shows how the system of “numerical control,” perfected at MIT and put into general industrial use, was chosen over competing systems for reasons other than the technical and economic superiority typically advanced by its promoters. Numerical control took shape at an MIT laboratory rather than in a manufacturing setting, and a market for the new technology was created, not by cost-minded professors, but instead by the U.S. Air Force. Meanwhile, completing methods, equally promising, were rejected because, among other reasons, they left control of production in the hands of the skilled workers, rather than in those of management or programmers. Thus, Noble demonstrates, engineering design in influenced by political, economic managerial, and sociological considerations, while the deployment of equipment—illustrated by a detailed case history of a large General Electric plant in Massachusetts—can become entangled with such matters as labor classification, shop organization, managerial responsibility, and patterns of authority.

In its examination of technology as a human, social process, Forces of Production is a pathbreaking contribution to the understanding of this phenomenon in American society.

Noble shows how the system of “numerical control,” perfected at MIT and put into general industrial use, was chosen over competing systems for reasons other than the technical and economic superiority typically advanced by its promoters. Numerical control took shape at an MIT laboratory rather than in a manufacturing setting, and a market for the new technology was created, not by cost-minded professors, but instead by the U.S. Air Force. Meanwhile, completing methods, equally promising, were rejected because, among other reasons, they left control of production in the hands of the skilled workers, rather than in those of management or programmers. Thus, Noble demonstrates, engineering design in influenced by political, economic managerial, and sociological considerations, while the deployment of equipment—illustrated by a detailed case history of a large General Electric plant in Massachusetts—can become entangled with such matters as labor classification, shop organization, managerial responsibility, and patterns of authority.

In its examination of technology as a human, social process, Forces of Production is a pathbreaking contribution to the understanding of this phenomenon in American society.

Specificaties

Betrokkenen

- Auteur(s):

- Uitgeverij:

Inhoud

- Aantal bladzijden:

- 409

- Taal:

- Engels

Eigenschappen

- Productcode (EAN):

- 9780307828507

- Verschijningsdatum:

- 22/01/2013

- Uitvoering:

- E-book

- Beveiligd met:

- Adobe DRM

- Formaat:

- ePub

Alleen bij Standaard Boekhandel

+ 20 punten op je klantenkaart van Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.