- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

Zoeken

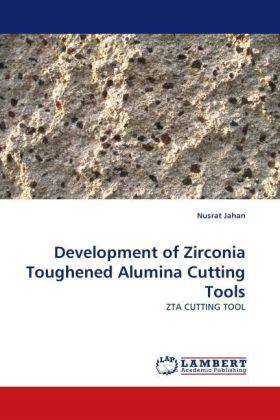

Development of Zirconia Toughened Alumina Cutting Tools

ZTA CUTTING TOOL

Nusrat Jahan

Paperback | Engels

€ 66,45

+ 132 punten

Omschrijving

Zirconia Toughened Alumina (ZTA) cutting tool inserts were produced successfully by compaction method using nanosized 75 wt% pure alumina and 25 wt% pure zirconia powders. Raw materials were milled and mixed with binder and then tablet shaped cutting tool inserts were prepared using 300 MPa pressure and 1400-1450°C sintering temperatures. Microstructures of the tool were observed and important mechanical properties were measured. Cutting tool inserts containing as little as 2.94% porosity were being able to produce at 1450°C with the maximum true density 4.12gm/cc (compared to 4.38 gm/cc for theoretical density) and hardness of 11.45 GPa. An increase in sintering temperature produced denser and harder cutting tool inserts. The microstructure of sintered inserts showed zirconia grains dispersed in alumina grains, a structure that is usually obtained in this product. The cutting performances of the prepared ZTA inserts could not be quantified due to inappropriate tool holder geometry. However, from the data it is clear that this cutting tool inserts, when operated properly, would give a much better machining performance than the ordinary metal and metal composite cutting tool.

Specificaties

Betrokkenen

- Auteur(s):

- Uitgeverij:

Inhoud

- Aantal bladzijden:

- 56

- Taal:

- Engels

Eigenschappen

- Productcode (EAN):

- 9783843368254

- Verschijningsdatum:

- 21/11/2010

- Uitvoering:

- Paperback

- Afmetingen:

- 152 mm x 229 mm

- Gewicht:

- 95 g

Alleen bij Standaard Boekhandel

+ 132 punten op je klantenkaart van Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.