- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

Zoeken

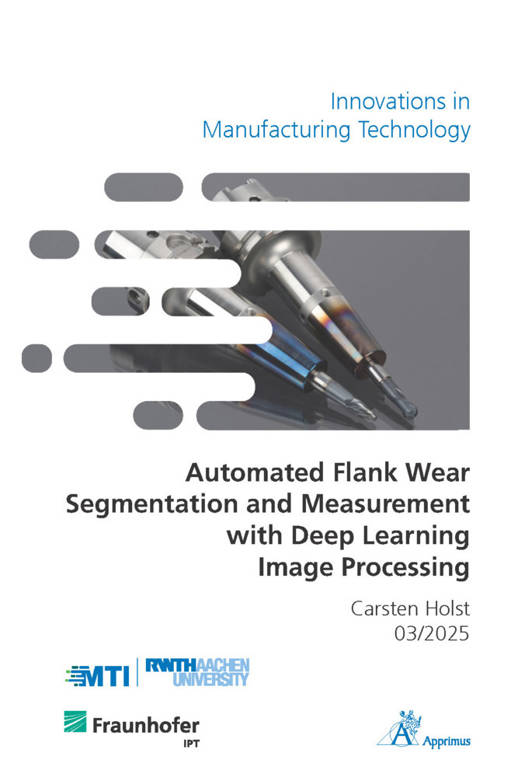

Automated Flank Wear Segmentation and Measurement with Deep Learning Image Processing

Carsten Holst

€ 53,45

+ 106 punten

Omschrijving

The aim of this thesis was to develop and optimize deep learning models specifically designed for the identification of tool wear on microscopic images of cutting tools and cutting tool edges. Cutting tool wear has an impact on dimensional accuracy and surface quality of parts, ultimately affecting the costs associated with meeting part quality criteria.To accomplish this objective, the creation of a tool wear model based on empirical tool life trials was conducted. An outcome of the trials was the generation of a dataset of images, which were then utilized to develop a deep learning model capable of segmenting cutting tool flank wear. To ensure the effectiveness of the deep learning model, a screening analysis was conducted to investigate various dataset properties and model hyperparameters that could influence the quality of predictions. The screening analysis helped identify the key factors that significantly impacted the performance of the model. Building upon the insights gained from the screening analysis, the thesis proceeded with an in-depth investigation of the most influential factors. This investigation led to the development of a decision model that could guide the selection of dataset-specific hyperparameters for optimal performance. To validate the effectiveness of the model optimization strategy, a machine tool integrated measurement setup was employed, utilizing a microscope as well as a camera. These use cases provided a practical assessment of the developed deep learning model and its ability to identify and assess tool wear in a real-world manufacturing scenario.By developing and refining deep learning models for tool wear identification on microscopic images, this thesis contributes to enhancing the understanding and management of tool wear in the manufacturing industry. The optimized models have the potential to facilitate timely maintenance interventions, minimize production errors, and reduce costs associated with part quality deviations. Moreover, the decision model for dataset-specific hyperparameter selection provides a valuable framework for researchers and practitioners working on similar image-based classification problems.

Specificaties

Betrokkenen

- Auteur(s):

- Uitgeverij:

Inhoud

- Aantal bladzijden:

- 182

- Taal:

- Engels

- Reeks:

Eigenschappen

- Productcode (EAN):

- 9783985552610

- Uitvoering:

- Paperback

- Afmetingen:

- 148 mm x 11 mm

- Gewicht:

- 347 g

Alleen bij Standaard Boekhandel

+ 106 punten op je klantenkaart van Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.