- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

- Afhalen na 1 uur in een winkel met voorraad

- Gratis thuislevering in België vanaf € 30

- Ruim aanbod met 7 miljoen producten

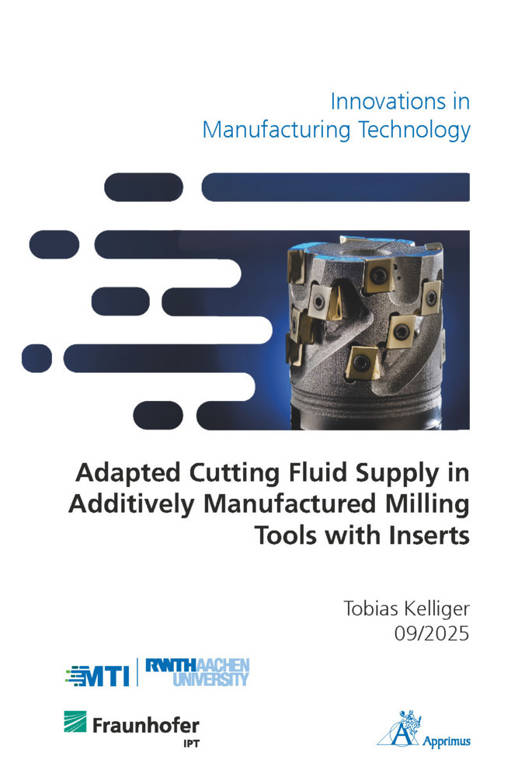

Adapted Cutting Fluid Supply in Additively Manufactured Milling Tools with Inserts

DE

Tobias Kelliger

€ 53,45

+ 106 punten

Omschrijving

The application of cutting fluid in milling is critical for efficient machining of challenging materials, such as titanium alloys used in aerospace applications. Tool-internal cutting fluid supply under elevated pressure has demonstrated improved tool life, productivity, and process reliability. However, conventional manufacturing of cutting tools with complex internal channel structures and nozzle designs is both costly and limited in geometric complexity. The design flexibility offered by additive manufacturing (AM) processes, such as Laser Powder Bed Fusion (PBF-LB), enables customized, individualized, process-adapted, and efficient cutting fluid supply systems.In this work, the internal, adapted cutting fluid supply in AM milling tools was first systematically investigated. The primary objective was to gain a deeper understanding of the cause-effect relationships between geometric supply design, cutting fluid process parameters, such as supply pressure and volume flow, and cutting parameters and their influence on thermo-mechanical tool load and resulting tool wear. First, PBF-LB-manufactured tangential shell-type indexable tools from 18MnCrMoV4-8-7 steel were evaluated, confirming operational readiness. Second, the geometric design of the internal cutting fluid supply in AM milling tools was examined. Based on fluid-mechanical analyses and machining experiments, design guidelines were developed that enable knowledge-based tool design. In milling of 42CrMo4+QT, tool life increased by up to 38 %, while in Ti-6Al-4V, it rose by up to 70 % compared to the conventionally manufactured reference tool. Third, thermal analyses, CFD simulations, and machining experiments enabled model-based process design. Rake face cooling with focused, highly energetic cutting fluid jets improved tool life in milling of Ti-6Al-4V, while lower supply pressure and non-focused jets reduced thermal cracks in 42CrMo4+QT. In a last step, the economic and ecological benefits of AM milling tools with adapted cutting fluid supply were confirmed through life cycle assessment and cost accounting. Ecological costs decreased by 15 % and operational costs by 21 % due to increased tool life. The optimal operating point depends mainly on energy consumption, process productivity, and insert consumption. A redesigned multi-row helical milling tool with an adapted cutting fluid supply tested in roughing of Ti-6Al-4V confirmed the industrial viability of the developed design approach.

Specificaties

Betrokkenen

- Auteur(s):

- Uitgeverij:

Inhoud

- Aantal bladzijden:

- 234

- Taal:

- Engels

- Reeks:

Eigenschappen

- Productcode (EAN):

- 9783985553068

- Uitvoering:

- Paperback

- Afmetingen:

- 148 mm x 14 mm

- Gewicht:

- 440 g

Alleen bij Standaard Boekhandel

+ 106 punten op je klantenkaart van Standaard Boekhandel

Beoordelingen

We publiceren alleen reviews die voldoen aan de voorwaarden voor reviews. Bekijk onze voorwaarden voor reviews.